Are you curious about how Flexibar Cables are made? Step inside Loganmex’s manufacturing facility for an exclusive look at the meticulous process behind producing these high-quality cables. From cutting and sizing to packing, each stage plays a crucial role in ensuring top-notch performance and reliability. Let’s dive in:

Cutting and Sizing: The process kicks off with precision cutting and sizing of raw materials to the required length. This step sets the foundation for consistency and uniformity throughout the production cycle, ensuring that each cable meets the desired specifications.

Stripping: Next up is the stripping stage, where the outer insulation of the cable is carefully removed to expose the conductive core. This precise operation demands skilled hands and specialized equipment to prevent damage to the core while maintaining the integrity of the cable.

Drilling: Drilling comes into play for cables that require additional components or connectors. Strategically placed holes are drilled to accommodate these elements, facilitating seamless integration into various applications.

Bending: Flexibility is key in Flexibar Cables, and the bending process is where this characteristic is honed. Advanced machinery applies controlled pressure to shape the cables according to specific bends or curves, ensuring optimal flexibility without compromising durability.

Adjustment: Fine-tuning is essential to address any deviations from the desired specifications. Skilled technicians meticulously adjust the cables to meet precise measurements and performance standards, guaranteeing consistency across the production line.

Visual Inspection: Nothing escapes the keen eye of our inspectors. Each cable undergoes a thorough visual inspection to detect any defects, imperfections, or irregularities. This meticulous scrutiny ensures that only flawless cables proceed to the next stage of the process.

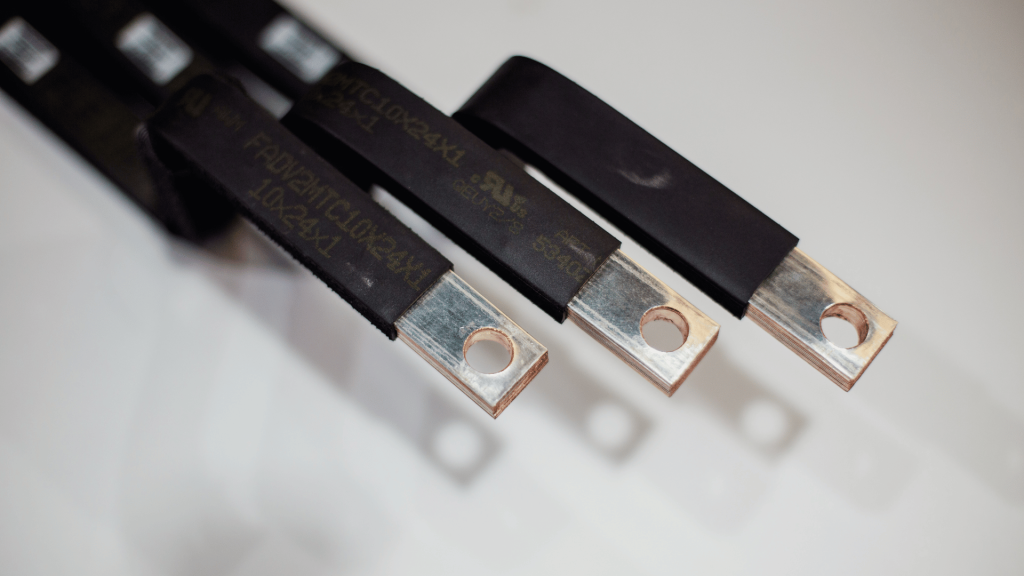

Label Placement: Proper labeling is vital for identification and traceability. Labels containing essential information such as product details, specifications, and safety warnings are carefully affixed to each cable, providing valuable insights for users and technicians alike.

Shrink Tubing: To enhance protection and durability, shrink tubing is applied to selected areas of the cable. This heat-sensitive material shrinks when heated, forming a tight seal around the cable and offering additional insulation against environmental factors and mechanical stress.

Electrical Test: Quality is non-negotiable, which is why each cable undergoes rigorous electrical testing to ensure optimal performance and reliability. Specialized equipment assesses conductivity, insulation integrity, and other electrical properties, guaranteeing compliance with industry standards.

Packing: The final stage brings everything together as the cables are carefully packed and prepared for distribution. From protective packaging to efficient labeling, every detail is meticulously executed to safeguard the cables during transit and storage.

At Loganmex, excellence is not just a goal; it’s our standard. The meticulous manufacturing process of Flexibar Cables reflects our unwavering commitment to quality, innovation, and customer satisfaction. Join us on our journey as we continue to push the boundaries of cable technology and redefine industry standards.