In the realm of electrical connections, precision and efficiency are paramount. Two crucial components often employed in various industries are cable assemblies and wire harnesses. Understanding their characteristics, differences, industrial applications, and the benefits they offer is pivotal for making informed decisions in engineering and manufacturing.

“Wire harnesses are the backbone of structured connections, while cable assemblies dance with flexibility in dynamic environments.”

Author – Unkkown

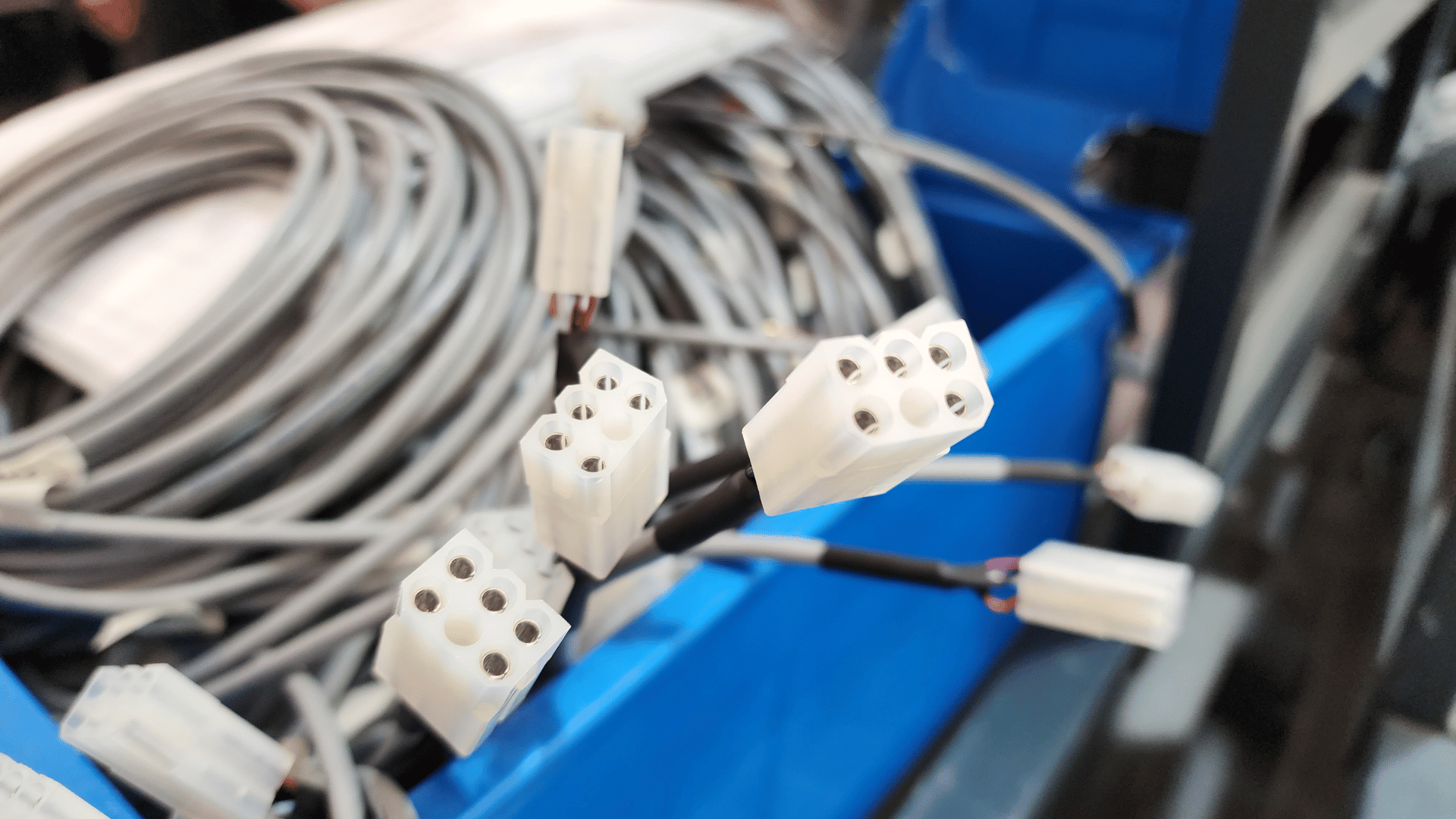

Cable Assemblies: A Flexible Solution

Cable assemblies consist of multiple cables or wires bundled together, often accompanied by connectors at their termination points. Their flexibility and adaptability make them suitable for applications requiring movement or maneuverability, such as robotics, aerospace, and automotive sectors. This flexibility allows for a dynamic range of motion without compromising on connectivity.

Wire Harnesses: Structured Precision

On the other hand, wire harnesses are a more structured and organized solution. These harnesses encompass multiple wires and cables precisely routed and secured within a protective sheath or conduit. They are ideal for static installations where maintaining precise connections in a fixed position is critical, such as in industries like telecommunications, industrial machinery, and appliances.

Key Differences

The fundamental disparity lies in their design and application. Cable assemblies are versatile and suited for dynamic environments where movement is a factor, while wire harnesses are more rigid and designed for static or fixed installations. Understanding the specific requirements of the project is vital to determine which solution best fits the need.

Industries Utilizing Cable Assemblies and Wire Harnesses

Both cable assemblies and wire harnesses find their applications across diverse industries. Cable assemblies are commonly seen in robotics, automotive systems, and aerospace technology. Wire harnesses, with their structured design, are prevalent in telecommunications, industrial machinery, and household appliances.

Benefits of Cable Assemblies and Wire Harnesses

The advantages of these solutions are numerous. Cable assemblies offer flexibility and mobility, reducing the risk of tangling or damage during movement. Wire harnesses ensure organized, fixed connections, reducing the risk of interference and enhancing the overall reliability of the system.

Loganmex: Tailoring Solutions to Specific Needs

For tailored cable assembly and wire harness solutions, Loganmex stands as a reliable manufacturer. They specialize in customizing these components to meet specific project requirements. With a comprehensive understanding of various industries and their unique needs, Loganmex offers engineering expertise to design and produce cable assemblies and wire harnesses with precision and reliability.

From concept to production, Loganmex’s experienced team collaborates closely with clients to understand the specific needs and design intricacies, ensuring that the final product aligns perfectly with the intended application.

In conclusion, the choice between cable assemblies and wire harnesses greatly depends on the specific demands of the project. Understanding their differences and the unique advantages they offer is fundamental in selecting the right solution to ensure optimal performance in diverse industries. Loganmex stands as a reliable partner in crafting tailored solutions for specific electrical connection needs.