At Loganmex, we take pride in our commitment to precision and quality in every step of our process manufacturing. Among the many crucial processes involved, stripping cables stands out as a fundamental step that ensures the integrity and efficiency of our final products.

What exactly is cable stripping, and why is it so important in our manufacturing process? Let’s delve into it.

“In the intricate landscape of process manufacturing, cable stripping emerges as a vital yet often overlooked step that plays a significant role in ensuring the reliability, performance, and safety of our products at Loganmex.”

Patricia Casillas – QA

Understanding Cable Stripping

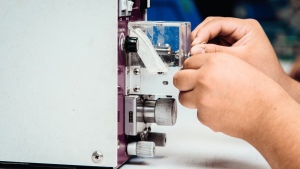

Cable stripping is the process of removing the insulation or outer jacket from electrical wires or cables to expose the conductor underneath. This step is essential in preparing cables for termination, splicing, or other electrical connections. Properly stripped cables facilitate secure connections, optimal conductivity, and overall safety in electrical systems.

Why it Matters at Loganmex?

-

Quality Assurance: Stripping cables with precision ensures that only the necessary amount of insulation is removed, preventing any damage to the conductor. This attention to detail is integral to maintaining the quality and reliability of our products.

-

Optimized Performance: Well-stripped cables offer superior conductivity, minimizing signal loss and maximizing the efficiency of electrical systems. This optimization is vital in meeting the performance standards expected by our customers.

-

Safety Compliance: By adhering to strict stripping standards and guidelines, we ensure that our products meet all safety regulations and industry standards. This commitment to safety underscores our responsibility to both our customers and our workforce.

-

Process Efficiency: Incorporating efficient cable stripping processes streamlines our manufacturing operations, reducing production time and costs while maintaining consistent quality across all our products.

Our approach to cable stripping

At Loganmex, we employ advanced stripping equipment and techniques to achieve precision and consistency in cable preparation. Our skilled technicians undergo rigorous training to master the art of cable stripping, understanding the nuances of different cable types, sizes, and insulation materials.

Moreover, we continuously evaluate and refine our stripping processes to stay abreast of technological advancements and industry best practices. This dedication to continuous improvement underscores our commitment to excellence in every aspect of our manufacturing operations.

In the intricate landscape of process manufacturing, cable stripping emerges as a vital yet often overlooked step that plays a significant role in ensuring the reliability, performance, and safety of our products at Loganmex. By prioritizing precision, quality, and efficiency in our cable stripping processes, we uphold our reputation as a trusted provider of high-quality electrical solutions.

At Loganmex, excellence isn’t just a goal—it’s our standard.